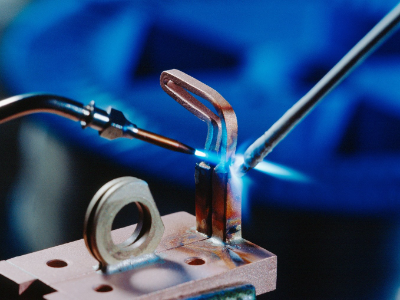

Brazing with Oxy Gas Flame

What is Brazing, How Is It Done?

The joining of different or same type metals with a heat source using an additional solder alloy that melts above 450 °C is called brazing. The joining process takes place with the metallurgical bond formed by the transfer of atoms called diffusion between the additive metal and the metals to be combined.

Where is Brazing Used?

The brazing process allows the economical joining of different types of materials with different cross-sectional thicknesses. Therefore, it is preferred in many sectors such as automotive, white goods, aviation and space industry, heating-ventilation, gas armatures production, food sector, and medicine sector. It is also widely used in pipe connections carrying oil, air and fuel where impermeability is important.

In brazing joints, in the metals to be joined, unlike welding, melting does not occur. Since there is no significant change in the crystal structure of the material, the homogeneity of the internal structure of the metal is preserved. As the brazing temperature is above 450 °C and lower than the melting temperatures of the soldered metals, deformations caused by high temperatures do not occur in the welded joints.

The molten metal solidifies by spreading between the parts to be brazed by capillary action (with capillary tube forces). It is recommended that in order to take advantage of the capillary effect, the spacing of the parts to be brazed should be set between 0.05-0.5 mm. In larger soldering intervals, the capillary effect cannot be benefited from.

All elements that will prevent the attachment and flow of the additive metal between the material surfaces to be joined should be removed before the brazing process. Elements such as oil, rust, and paint on the material surface cleaned by brush, sandpaper or suitable chemical methods should be taken to the brazing process without waiting for too long.

When the brazing process of the surface-cleaned materials is started, oxide formation starts on the surfaces due to the heat. Fluxes are used to prevent and clean this oxide formation. Fluxes melt 50 °C before the operating temperature, increasing the fluidity of the additive metal while cleaning the oxide.

The selection of fluxes that prepare the melt joint zone for brazing before the filler metal is made according to the filler metal. While GeKaTec FLUX F-SH1 fluxes are used for the use of silver alloy brazing rods, it will be appropriate that GeKaTec FLUX F-LH1 fluxes are preferred for brazing aluminum and its alloys. The selection of these related fluxes is determined by the melting temperatures of the materials to be brazed.

Self-flux coated brazing rods such as GeKaTec L-Ag20 FC or GeKaTec L-Ag40 FC provide convenience to the user in practice. In addition, since GeKaTec S5 brazing rods, which are frequently preferred, have very high fluidity, they can be used without flux in joining copper to copper.

In the selection of the additive metal, it is desired that the melting point of the main metal be at least 200 °C higher than the melting point of the additive metal. Color compatibility can also appear to us as an important criterion in the selection of additional filler materials that are expected to match the mechanical properties of the main material to be brazed.

Flame Types in Oxy-Gas Flame Brazing

Neutral Flame: It is the type of flame in which the ratios of combustible gas (acetylene) and oxygen are equal. It is generally preferred for brazing metals such as steel and copper.

Carburizing Flame: Flames with high flammable gas ratio are called carburizing flames. Its burning is calmer. Its flame cone is longer than normal flame. It is preferred in brazing of cast irons, in order to prevent oxygen content in brazing of aluminum and its alloys, the surface of which is easily oxidized.

Oxidizing Flame: It is the type of flame with high oxygen ratio. Its burning is harsh. The highest temperature values are reached in this type of flame. It is used for brazing brass having zinc evaporation problem.