Gedik R&D Center Takes the Lead in Competition by Investing in Innovation and Technology

GEDİK R&D CENTER GAINS A COMPETITIVE EDGE

Gedik Termo Valve and Gedik Advanced Casting Technologies have been keeping abreast of technological developments since their formation while designing products meeting the requests and demands of their customers and increasing customer satisfaction.

To this end, they are constantly investing in R&D. The R&D Department is according priority to planning, executing, overseeing, and verifying of all R&D activities from the design and development processes to the development of product portfolio to be designed/developed.

Composed of more than 20 engineers and technicians, the R&D team continues carrying out design and development activities in order to add new products to our range of products and improving existing products in light of priority customer demands while closely following sector-specific developments, user needs, and technological developments.

GEDİK VALUES INNOVATION

Gedik Termo Valve and Gedik Advanced Casting Technologies R&D Manager Hüseyin Tunca,

says that they were poised introduce 30 new products by the end of 2023. He went on to say: “We value innovation. In 2024, increasing the number of people in of our R&D team and diversifying our product range by launching 100 new products are among our top goals.”

Working on new products to be offered to customers under the leadership of R&D Manager Hüseyin Tunca, Gedik R&D is integrating its engineering works with ERP.

Pressing ahead with the aim of both increasing employee satisfaction and bringing product costs and quality to levels that we have set, Gedik R&D

is carrying out its design and product development works in solid modeling programs. It also supports efforts to launch new products by performing advanced engineering mechanical, flow, static, and thermal analyses, using analysis programs.

WHAT NEW PRODUCTS ARE BEING DEVELOPED IN THE R&D CENTER?

Gedik R&D Manager Hüseyin Tunca says, “We are proud of being a few steps ahead of our competitors because we achieve fast, scientific, and theoretical results by saving both time and cost in the process, starting with the prototype stage and ending in the mass production of new products after developing their molds and models by means of a 3D printer machine at the prototype stage.”

Noting that all tests conducted in Gedik Termo Valve and Gedik Advanced Casting Technologies were carried out by certified personnel specialized in their fields, Tunca went on to say: “We conduct all test and analyses, including leakage, tensile, bending, fracture, hardness, notch and compression tests, fatigue analyzes, metallographic inspections, SAM images, and weld penetration analyses by using scientific methods.

COOPERATION BETWEEN ACADEMIA AND INDUSTRY

Technical training for Gedik’s R&D team is provided by by expert instructors at in Istanbul Gedik University.

Gedik R&D Department, which laid the foundations of literature research studies through TEYDEP, TÜBİTAK and KOSGEB projects, provides required resources for projects jointly carried out by the academia and industry and files applications with appropriate institutions and organizations. Hüseyin Tunca said, “All members of the team are making strenuous efforts to achieve our goal of becoming a Gedik Termo Valve and Gedik Advanced Casting R&D Center as soon as possible.

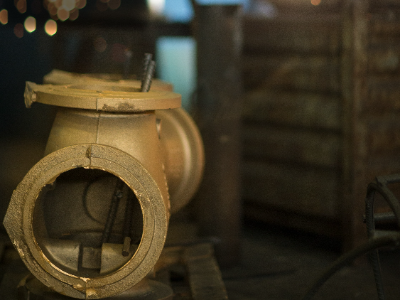

Our team of experts carries out out all pig iron, ductile iron, bronze, steel, stainless steel, and precision casting processes in our foundry.

We know very well that, without compromising on product quality, we are working hard to become the leader of the industry in domestic and foreign markets by understanding customer requests in the shortest time possible and designing reliable and competitive products.”