Laser Welding Technology: Fast, Efficient and Environmentally Friendly

Fast and Efficient: The Power of Laser Welding Technology!

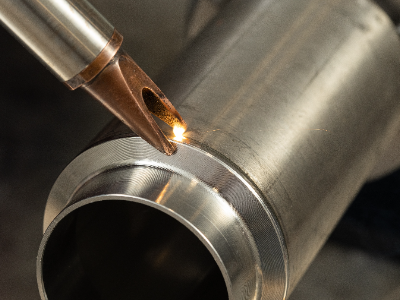

Laser welding technology, which is rapidly increasing in use due to its fast and efficient compared to conventional welding methods, enables welding and cutting with low heat input and minimal deformation.

Easy to Use, No Professional Knowledge Required: Laser Welding Advantages

It is very easy to use and eliminates the need to be an experienced welder as it does not require professional knowledge and experience to weld. The fact that it is much faster than traditional welding methods is one of its salient features.

Environmentally Friendly and Energy Efficient: The Environmental Contribution of Laser Welding

The laser's photoelectric conversion efficiency results in up to 30% less energy consumption and is therefore environmentally friendly. Thanks to the very low heat input in the laser welding process, penetrating, deformation-free and resistant welds can be obtained even in the thinnest materials.

Fiber laser welding machines, which are available in our product range with 3 different power options as GeKaLaser 1000, GeKaLaser 1500, GeKaLaser 2000, offer the possibility of cutting and cleaning as well as joining various materials such as unalloyed steel, stainless steel, aluminum, copper, brass with the 3IN1 feature, while eliminating additional labor costs as there is no need for leveling and grinding processes after welding with continuous welding mode.

Precise Solutions for Different Sectors

Our GeKaLaser Laser Welding machines offer precise solutions in many applications and sectors such as industrial kitchen manufacturing, furniture shelf and scaffolding manufacturing, machinery manufacturing, railing and window manufacturing, advertising and lighting sector, automotive, medical, aviation sector.