Welding BLOG

What is a Welding Glove?

What is a Welding Glove?A welding glove is personal protective equipment used to protect the operator’s hands during welding operations against high heat, sparks, splashes of molten metal, mechanical impacts, and electrical risks.Since the risks that occur during welding directly affect the hands and wrist parts, the correct usege of welding gloves has critical importance for both occupational safety and work efficiency.Functions of Welding GlovesA welding glove does not only provide protection; it also affects welding performance:Provides protection against high temperaturesProvides protection against high temperaturesOffers resistance to mechanical impactsImproves hand control and grip strength during weldingEnsures comfort during long working periodsUsing unsuitable gloves can lead to serious occupational accidents and loss of workforce.Things You Need to Know When Choosing Welding Gloves1. Suitability for the Type of Welding PerformedThe welding method is a determining factor in glove selection:MIG/MAG Welding: Heat-resistant gloves with medium flexibilityTIG Welding: Thinner gloves offering high finger sensitivityElectrode (MMA) Welding: Thick gloves with high heat and spatter protectionSince each welding method involves different risks, a single type of glove is not suitable for every application.2. Heat and Flame ResistancyWelding gloves must be produced from materials that are resistant to high tempatures. Commonly preferred materials include:Heat-resistant leather (cowhide, goatskin, or sheepskin)Flame-resistant stitching threadsLong-cuff designsInsufficient heat protection can lead to a serious risk of burns.3. Balance Between Glove Thickness and FlexibilityThe thicker the glove, the higher the level of protection; however, flexibility decreases.Therefore:Thinner and more flexible gloves should be preferred for precision workThicker gloves should be used for heavy-duty and intensive welding applicationAchieving the right balance improves both safety and welding quality.4. Wrist and Forearm ProtectionDuring welding, splashes can harm not only the hands but also the wrists and forearms.Therefore:Gloves with long cuffsDesigns that fully cover the wristprovide extra protection and enhance occupational safety.5. Standards and CertificationsWelding gloves must comply with relevant occupational safety standards.Particularly;EN 388 (mechanical risks)EN 407 (heat and fire risks)products that meet the above-mentioned standards should be preferred.6. Comfort and Long-Term UseWelding operations often involve long working periods. Therefore:Inner linings that reduce sweatingErgonomic cutsNon-slip surfacesincrease operator comfort and work efficiency.Safe and Professional Welding Practices with Gedik WeldingGedik Welding supports a professional approach not only in consumables and machines but also in occupational safety and the proper use of equipment. Choosing the right protective equipment is as important as achieving high-quality welding.ConclusionWelding gloves are one of the fundamental elements of welding safety. Choosing the right gloves protects the operator and ensures that welding operations are carried out in a more controlled, safe, and efficient manner. Using appropriate gloves according to the type of welding and working conditions plays a critical role in preventing occupational accidents.

What Are the Types of Welding?

The Most Common Welding Methods Used in IndustryWhat Are the Types of Welding?Welding types refer to the different techniques used to join metals or thermoplastic materials by applying heat, pressure, or a combination of both. Each welding method offers distinct advantages in terms of the equipment used, application areas, welding quality, and cost.Choosing the right welding method is critical for production quality and achieving long lasting joints.The Most Commonly Used Welding TypesElectrode (Arc) Welding – MMAUses a coated electrodeSuitable for open-air and field workRequires simple equipmentCommonly preferred in construction, maintenance, and heavy industry.MIG/MAG WeldingContinuous wire-fed welding methodProvides high speed and efficiencySuitable for automation Frequently used in automotive, mass production, and manufacturing lines.TIG WeldingUses a non-consumable tungsten electrodeProvides high weld quality and precisionIdeal for thin materialsPreferred for stainless steel, aluminum, and precision manufacturing.Gas WeldingUses oxygen and combustible gases Portable and simple methodLimited heat control Generally used for repairs and small-scale applications.Plasma WeldingHas high energy densityProvides deep penetrationPrecise and strong welding methodUsed in defense, aerospace, and advanced engineering applications.Laser WeldingUses a concentrated laser beamOffers low distortion and high speedSuitable for automation and robotic systemsProminent in automotive and high-precision manufacturing.Resistance WeldingJoins materials using electrical resistance and pressureSuitable for mass productionIncludes spot and seam welding applicationsCommon in the home appliance and automotive industries.Things You Should Know When Choosing Welding Types1. Base Material TypeThe material to be welded directly determines the method:Carbon steelsStainless steelsAluminum and its alloysCast ironEach material requires different heat input and welding technique.2. Material ThicknessTIG or laser welding for thin sheetsMIG/MAG or electrode welding for thick sectionsChoosing the wrong method can cause deformation or insufficient penetration.3. Production Speed and CostMass production: MIG/MAG, resistance, or laser weldingLow-volume jobs: Electrode or TIG weldingChoosing the right method optimizes costs and production time.4. Weld Quality and Strength RequirementsIn critical applications, the following should be considered:Weld seam qualityMechanical strengthStandards and certification requirements5. Working EnvironmentOpen areas: Electrode weldingClosed and controlled environments: MIG/MAG, TIG, laserEnvironmental conditions affect the success of the welding method.6. Operator Experience and EquipmentSome welding methods require:Higher operator skillAdvanced equipment and automationThe existing infrastructure should be properly evaluated.Gedik Welding and the Right Welding TechnologyGedik Welding supports businesses in choosing the right welding technology by providing welding machines, welding consumables, and technical consultancy services for various industries. It combines quality and efficiency with solutions tailored to production needs.ConclusionChoosing the right welding method from among the various types is a strategic decision in terms of production quality, cost, and workplace safety. A proper selection based on material type, production volume, and quality expectations ensures durable and reliable welded joints.

What is a Welding Arc? How It Forms and Its Effects on Welding Quality What is a Welding Arc?

What is a Welding Arc? How It Forms and Its Effects on Welding QualityWhat is a Welding Arc?A welding arc is a high-temperature, controlled electrical plasma discharge that occurs between the electrode of the welding machine and the base metal. This arc melts the metal surfaces and creates a weld pool, allowing the parts to be permanently joined.Arc welding methods form the foundation of the most widely used welding techniques in the industry.How Does a Welding Arc Form?The formation of a welding arc occurs in three main stages:The electrode comes into contact with the workpiece.When the contact is broken, the electric current becomes ionized.An arc is generated between the electrode and the metal.The temperature of this arc can reach approximately 6,000–8,000°C. The resulting high heat allows the base metal and filler metal to melt in a controlled manner.Functions of the Welding ArcThe welding arc is not just a source of heat. It also:Melts the base metalTransfers the filler metal into the weld poolDetermines the shape of the weld beadAffects weld penetration and strengthTherefore, having a stable and controlled arc is critically important for welding quality.Types of Welding ArcsThe characteristics of the arc vary depending on the welding method:Short ArcSuitable for thin materialsLess spatterControlled heat inputSpray ArcOperates at high currentProvides deep penetrationPreferred for thick sectionsPulsed ArcBalances heat inputLow spatterHigh weld qualityIn particular, in modern MIG/MAG and TIG welding machines, arc control is digitally optimized.Factors Affecting Welding Arc StabilityFor a welding arc to remain stable, the following factors are important:Correct current and voltage settingsProper selection of electrode or wireType and flow rate of shielding gasTorch angle and welding distanceArc control technology of the welding machineIncorrect settings can cause spatter, porosity, insufficient penetration, and weak weld formation.The Relationship Between Welding Arc and Welding QualityA stable welding arc results in:Smoother and more aesthetically pleasing weldsHigher mechanical strengthLess need for reworkLower consumption of consumablesThis provides advantages in production in terms of time, cost, and quality.Gedik Welding with Controlled and Powerful Arc PerformanceGedik Welding offers maximum performance in industrial welding applications through welding machines equipped with advanced arc control technologies, as well as high-quality welding wires and electrodes. Our products adapt to different arc characteristics, helping to achieve stable, reliable, and repeatable welding results.ConclusionThe welding arc is the heart of the welding process. Proper formation and control of the arc directly affect the strength, appearance, and performance of the weld. A welding arc created with the right equipment and correct parameters is the key to long-lasting and reliable joints.

Things You Should Know While Choosing Casting Electrodes

Things You Should Know While Choosing Casting ElectrodesStrong Welds with Low Risk of Cracks Using the Right ElectrodeWhy Is Electrode Selection Critical in Casting Welding?Casting materials are among the most difficult materials to weld due to their high carbon content, brittle structure, and heterogeneous microstructure. Incorrect electrode selection can lead to serious problems such as post-weld cracking, breakage, hardening, and loss of machinability.Therefore, choosing the right electrode for casting welding is a fundamental factor for welding success.1. Correctly Identify the Type of Casting MaterialBefore selecting an electrode, the type of casting material to be welded must be clearly identified:Gray cast ironDuctile (spheroidal graphite) ironMalleable (tempered) ironWhite cast ironSince each type of casting has different mechanical properties, using a single type of electrode is not appropriate.2. Prefer Nickel-Based ElectrodesNickel-based electrodes are the most common and reliable choice in casting welding.Pure nickel electrodes:High machinabilityLow risk of crackingIdeal for precise and repair weldsNickel-iron (Ni-Fe) electrodes:Higher mechanical strengthSuitable for parts subjected to heavy loadsThe correct alloy should be selected according to the purpose of the application.3. Consider Post-Weld Machinability RequirementsIf machining will be performed after welding, the electrode selection should be suitable for this purpose.Pure nickel electrodes → high machinabilityHigh-iron electrodes → harder structureThis criterion must be taken into account for repair and maintenance applications that require machinability.4. Electrode Selection to Minimize Cracking RiskThe greatest risk in casting materials is cracks that form during cooling. Therefore, electrodes should be chosen that:Have low hydrogen contentFeature designs that control heat inputUse alloys that provide elastic and tough weld metal5. Welding Method and Application ConditionsIn casting welding, the following are generally applied:Electrode (MMA) weldingLow amperageShort welds (step welding)The electrode must be suitable for these working conditions.6. Consider Preheating and Cooling ConditionsElectrode selection should also take into account the preheating method to be applied:Preheated weldingCold welding (without preheating, controlled)Some electrodes are more suitable for use with low preheating.7. Standards and Application SafetyThe selected casting electrode should:Comply with EN, ISO, or AWS standardsBe suitable for the welding positionHave clear application instructionsThese criteria are of great importance for industrial safety and quality.Reliable Solutions in Casting Welding with Gedik WeldingGedik Welding offers nickel-based casting electrodes developed for casting repair and manufacturing applications, providing welds that are durable, machinable, and have a low risk of cracking. With technical support and proper product guidance, it helps achieve reliable results in casting welding. ConclusionSelecting a casting electrode is not just a choice of consumable; it is a strategic decision that directly affects post-weld performance. By choosing an electrode that matches the type of casting, machinability requirements, and working conditions, strong, reliable, and long-lasting welded joints can be achieved.

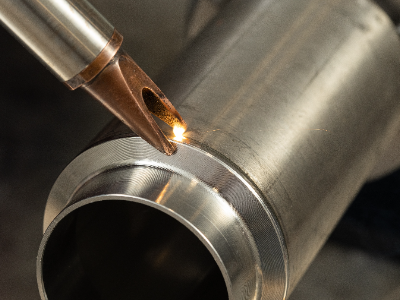

What is Pipe Welding?

What is Pipe Welding?Pipe welding is the process of joining pipes that carry liquids, gases, or steam in a leak-proof and durable manner using welding techniques. It is critically important for the safe operation of pipelines in energy, petrochemical, construction, infrastructure, and process facilities.Since welded pipes operate under high pressure and temperature, pipe welding requires greater precision and technical expertise compared to standard welding applications.The Importance of Pipe WeldingWelds in piping systems:Directly affect system safetyDetermine the risk of leaks and explosionsEnsure the long-term operation of the facilityTherefore, using the correct welding method, appropriate welding consumables, and controlled application is of vital importance in pipe welding.Most Common Pipe Welding MethodsElectrode (MMA) WeldingCommonly used in field applicationsSuitable for outdoor conditionsParticularly preferred for root pass weldingFrequently used in maintenance, repair, and installation work.TIG WeldingProvides high weld quality and precisionIdeal for thin-walled pipesPreferred for stainless steel and alloy pipesCommonly used for root pass welding in critical lines.MIG/MAG WeldingOffers high speed and efficiencyEffective for thick-walled pipesSuitable for mass production and workshop environmentsFrequently used for filler and cover passes.Orbital WeldingProvides automatic and repeatable weldingMinimizes human errorIdeal for lines requiring hygiene and precisionPreferred in food, pharmaceutical, and semiconductor facilities.Welding Positions Used in Pipe WeldingPosition information is critical in pipe welding:1G / PA: Flat position2G / PC: Horizontal position5G: Fixed pipe – horizontal axis6G: Fixed pipe – inclined (most difficult position)Especially 5G and 6G positions are important criteria for welder qualification.Key Considerations in Pipe WeldingFor successful pipe welding:Pipe ends should be properly prepared (beveling, chamfering)Root gap and alignment must be correctly setAppropriate electrode or filler wire should be selectedHeat input should be applied in a controlled mannerPost-weld inspections must be conductedThese steps significantly reduce the risk of cracks and leaks.Where is Pipe Welding Used?Pipe welding plays a critical role in many industries:Oil and natural gas pipelinesPower plantsChemical and petrochemical facilitiesHeating, cooling, and air conditioning systemsIndustrial process linesIn these areas, weld quality is directly related to operational safety.Reliable Solutions in Pipe Welding with Gedik WeldingGedik Welding provides industrial-standard solutions for pipe welding applications with high-performance welding machines, wires, and electrodes. Thanks to its technical expertise and product variety, it supports achieving optimal welding performance for different pipe diameters and materials. ConclusionPipe welding is a critical application that requires high safety, strength, and leak-proof performance. With the correct welding method, appropriate consumables, and experienced application, it is possible to create long-lasting and reliable piping systems.

What is Aluminum Welding?

What is Aluminum Welding?Aluminum welding is the process of joining aluminum and aluminum alloys—known for their light weight, high corrosion resistance, and thermal conductivity—using appropriate welding methods. It plays a critical role in many industries, from automotive to aerospace, defense, and construction.However, the physical and metallurgical properties of aluminum make the welding process more delicate compared to traditional metals like steel. Therefore, proper equipment, consumables, and technical knowledge are of great importanceFactors That Make Aluminum Welding DifficultAluminum welding comes with some specific challenges:High thermal conductivity: Heat spreads quickly, making it difficult to control the weld pool.Oxide layer (Al₂O₃): This naturally forming layer on aluminum surfaces has a higher melting point than the base metal.Low melting point: Excessive heat input increases the risk of burning and distortion.Porosity formation: Improper shielding gas or surface contamination can lead to porosity in the weld.For these reasons, aluminum welding requires experience and the right technology.The Most Common Aluminum Welding MethodsTIG (GTAW) WeldingThis is one of the most frequently preferred methods for aluminum welding.High weld qualityPrecise heat controlIdeal for thin materialsThe use of AC current effectively breaks the oxide layer.MIG (GMAW) WeldingPreferred for mass production and thick sections.High speedAutomation compatibilityProduction efficiencyThe wire feeding system and correct wire selection are critical in aluminum MIG welding.Lazer WeldingUsed in applications requiring high precision and minimal distortion.Narrow HAZ (Heat-Affected Zone)High speed and repeatabilityCommonly used in automotive and aerospace industriesCorrect Selection of Welding Consumables in Aluminum WeldingFor successful aluminum welding, the following are required:Appropriate aluminum wire (e.g., AlSi or AlMg alloys)Correct shielding gas (usually pure argon or an argon–helium mixture)Cleaned and oxide-free surfaceIncorrect selection of welding consumables directly affects mechanical strength and overall weld quality.Tips to Improve Quality in Aluminum WeldingAlways clean the surface before weldingApply heat input in a controlled mannerSelect the correct current type and parametersUse a welding machine and torch suitable for the applicationProfessional equipment and proper settings significantly reduce the risk of defective weldings.Reliable Aluminum Welding Solutions with Gedik WeldingGedik Welding provides reliable solutions for industrial applications through high-quality welding wires, welding machines, and technical consulting services for aluminum welding. With products specifically developed to meet the needs of different industries, we bring together quality and efficiency in production processes.ConclusionWhen aluminum welding is applied with the correct method, appropriate consumables, and proper technical knowledge, it provides high-strength and long-lasting joints. To meet quality standards in industrial production, it is of great importance to choose welding solutions that are compatible with the nature of aluminum.

What is plasma cutting?

What is plasma cutting?Plasma cutting is a process of cutting conductive metals using a high-temperature stream of ionized gas (a plasma arc). This method, created by combining electrical energy with gas transformed into plasma, forms the basis of fast, clean, and high-precision cutting operations in today’s industry.Plasma is the ionized state of gas formed through high temperature and electrical energy. This ionized gas exits a narrow nozzle at high speed and instantly melts the metal it comes into contact with, creating the cut. Thanks to the intensity of the arc energy, the cut line is narrow and clean, making plasma cutting a versatile solution in the industry.How Does Plasma Cutting Work?The plasma cutting process essentially takes place through the following steps:The power supply creates an electric arc between the electrode at the torch tip and the workpiece.The gas passing through the torch (air, nitrogen, oxygen, argon–hydrogen mixtures) is transformed into plasma by the effect of this arc.The plasma exits the narrow nozzle at high speed and strikes the surface of the material.The metal melts due to the plasma’s temperature, which can reach 20,000–30,000 °C.The molten metal is ejected at high pressure in the cutting direction, and the cut is completed. This process provides higher speed, greater control, and a smoother cut surface than a torch cut.Where Is Plasma Cutting Used?Plasma cutting is preferred in many industries thanks to its high speed, high precision, and broad material compatibility, including:Steel constructionShipbuilding and shipyardsAutomotive and heavy industryAgricultural machinery manufacturingPressure vessel and boiler fabricationMetal furnitureMaintenance and repair workshopsCNC plasma cutting machinesIndustrial production linesIt can be used in both manual torch systems and CNC-controlled automatic machines.Chracteristics of Plasma CuttingThe main characteristics that distinguish plasma cutting from other methods:Extremely high temperature and speedSmooth cutting of both thin and thick materialsPrecise contour cutting (holes, cavities, shapes)Narrow heat-affected zone (HAZ)Ability to cut metals that cannot be cut with oxygenSuitable for both manual and CNC useIt is one of the most efficient methods, especially for carbon steel, stainless steel, and aluminum.Which Materials Can Plasma Cutting Be Used On?Plasma cutting can be applied to all electrically conductive metals:Carbon steelStainless steelAluminumCopper and copper alloysCast ironTitaniumThese are materials that are difficult or impossible to cut using oxy-fuel cutting.Advantages of Plasma CuttingPlasma technology offers numerous advantages in both manual use and CNC machines: 1. High Cutting SpeedPlasma is significantly faster than traditional oxy-fuel cutting.For example, it can cut 10 mm sheet metal 3–5 times faster.2. Clean and Smooth Cut Surface Thanks to its high arc energy, slag formation is minimal.This reduces the need for post-cut grinding.3. Versatile Application It delivers effective results in all types of cutting, such as: Thick sectionsThin sheetsManuel cuttingCNC cutting4. Wide Material Compatibility It performs well even on materials that cannot be cut with oxygen.5. Low Heat Impact Thanks to its narrow heat-affected zone (HAZ), the risk of metal distortion is reduced.6. Cost-Effective Long-lasting consumablesLow energy consumptionHigh cutting speed reduces overall production costsTypes of Plasma Cutting1. Manual Plasma Cutting These are cuts made with portable plasma cutting machines.Ideal for service and maintenance teams, workshops, and small businesses.2. CNC Plasma Cutting Computer-controlled, high-precision cutting.Preferred for thick plates, heavy workloads, and mass production.3. Hyper Plasma / High-Performance Systems It is used in jobs requiring high-level quality by offering the following:• A narrower arc• Higher speed• Minimum slope on the cutting surfaceWhich Gases Are Used for Plasma Cutting? Different gases affect cutting performance and edge quality:Air → Most common and economicalOxygen → High speed on carbon steelNitrogen → Good surface finish on stainless steel Argon–Hydrogen → Thick and precise stainless steel cuts Argon → Thin materials Compressed air is generally preferred in manual machines.How to Choose a Plasma Cutting Machine?When selecting the right plasma cutting machine, the following criteria are important:1. Cutting Capacity (mm)The machine’s piercing ability, quality of cut, and maximum severance cutting values should be considered.2. Power (Amperage)• 40–60 A → Thin sheets• 80–120 A → Medium thickness• 120 A and above → Heavy industry3. Duty CycleA high duty cycle is critical for businesses with intensive production.4. Consumable LifespanThe durability of torch consumables directly affects operating costs.5. Compressor Requirement Some plasma machines have built-in compressors, while others require an external compressor.6. CNC Compatibility Important for businesses planning automation investments.7. Portability Light and compact models are preferred for field and service work.ConclusionPlasma cutting is a modern metal cutting method that offers speed, precision, cost-effectiveness and broad material compatibility. This technology, used on both manual and CNC machines, enhances production quality and efficiency across numerous industries.Selecting the correct plasma machine; determining the right power, gas and consumable combination is critical as it directly affects cutting quality, cost and production speed.

What is a Gas Shielded Welding Machine?

What is a Gas Shielded Welding Machine?A gas metal arc welding machine is an essential piece of equipment used to join metal materials under a protective gas atmosphere. Operating with the MIG (Metal Inert Gas) and MAG (Metal Active Gas) methods, these machines are widely used in industrial manufacturing thanks to their speed, efficiency, and low spatter performance.Gas-shielded welding machines use a semi-automatic system in which the consumable wire is continuously fed to the torch. The shielding gas isolates the molten weld pool from oxygen, and moisture in the atmosphere, ensuring a clean, smooth, and strong weld seam.Working Principle of Gas Shielded Welding MachinesGas shielded welding machines convert the electrical energy they receive from the network into a controlled welding current. Then:1. The wire is fed from the wire feed unit to the torch.2. The shielding gas is distributed from the torch to the welding area.3. The electric arc formed between the wire and the base material melts the metal.4. The molten metal pool cools under the shielding gas, forming the weld bead.This process offers the operator advantages such as high welding speed, stable arc, low heat input, and reduced cleaning requirements.The Difference Between MIG and MAGWhen referring to gas shielded welding machines, we discuss two fundamental methods:MIG Welding (Metal Inert Gas)• Inert gas (argon, helium) is used.• It is suitable for non-reactive materials such as stainless steel, aluminium and copper alloys.• The weld quality is high.MAG Welding (Metal Active Gas)• Active gas (CO₂ or argon–CO₂ mixture) is used.• It is the most common method for carbon steels and structural steels.• Production speed is high, and the cost is low.Basic Components of a Gas Shielded Welding MachineA gas shielded welding system consists of the following parts:• Welding power source (inverter or transformer type)• Wire feed unit• Welding torch• Gas cylinder and regulator• Grounding clamp and cables• Control panel• Consumables (welding wire, nozzle, contact tip, etc.)Modern inverter based models have become the preferred choice for businesses, offering more precise arc control and energy efficiency.Advantages of Gas Shielded Welding MachinesGas shielded welding machines stand out in industrial production with the following benefits:• High welding speed → Ideal for mass production• Low spatter rate → Cleaner welds, less grinding• High-quality and uniform weld appearance• Superior performance on thin sheets• Compatibility with automation and robotic applications• Easy to learn operation• Long uninterrupted welding capabilityFor these reasons, it is the most widely used welding method in the automotive, metal furniture, shipbuilding, steel construction, machine manufacturing, and white goods industries.Where are Gas Shielded Welding Machines Used?Gas shielded welding machines are used in a wide range of industrial applications:• Automotive and related industries• Shipbuilding and heavy industry• Steel construction• Metal furniture production• Pipe and profile manufacturing• Thin sheet metal and stainless steel work• Workshop production and maintenance-repair work• Robotic welding linesIts compatibility with both manual and robotic applications gives this method a strategic position in production lines.How to Choose the Right Gas Shielded Welding Machine?The following criteria should be considered when selecting a machine:• Current range and duty cycle• Suitable power for material thickness• Wire feed quality and stability• Gas type and area of use• Inverter or transformer preference• Portability requirement• Energy efficiency• Consumable compatibility• Service network and spare part availabilityA correctly selected gas welding machine provides long-term advantages to businesses by increasing both production quality and energy savings.

What Is a Pressure Regulator in Welding? Key Points to Know When Choosing One

What Is a Pressure Regulator in Welding? Key Points to Know When Choosing OnePressure regulators are critical equipment used in welding operations to ensure a safe, stable, and controlled gas flow. In MIG/MAG, TIG, and oxy-fuel welding applications, they reduce the high pressure from the gas cylinder to a suitable working pressure. Therefore, the regulator is an essential component for both welding quality and operator safety.A pressure regulator reduces the pressure in the gas cylinder, maintains a stable output pressure, and prevents fluctuations in gas flow during operation. If not properly selected, it can lead to poor weld quality, increased gas consumption, or potential safety hazards.What Is a Pressure Regulator? A pressure regulator reduces the high pressure in gas cylinders to a controllable working pressure. In welding applications, it determines:The pressure at which the gas exits,The flow rate of the gas,Whether the gas flow remains stable.Generally, it has a two-gauge structure: Cylinder Pressure Gauge: Indicates the high pressure inside the cylinder (usually 150–200 bar).Output Pressure Gauge: Shows the working pressure required for welding (e.g., 10–15 L/min for MIG/MAG).Regulators are designed differently depending on the type of gas used. Which Gases Are They Used With?Pressure regulators work with different gases depending on the welding method used:MIG/MAG (Gas Shielded) → Argon, CO₂, Argon–CO₂ mixturesTIG Welding → Argon, HeliumOxy-Gas Cutting and Welding → Oxygen and acetyleneBrazing → Propane, LPG, special mixtures Different connection standards and internal designs are used for each gas. Therefore, using an incompatible regulator is both dangerous and inefficient.Functions of a Pressure RegulatorThe pressure regulator performs tasks that ensure both the quality and safety of the welding process: Reduces cylinder pressure to the working pressureMaintains a stable output pressure (prevents pressure fluctuations)Controls gas flowEnsures operator safetyOptimizes gas consumptionEspecially in MIG/MAG and TIG welding, achieving a high-quality weld is impossible without a stable and accurate gas flow.Types of Pressure RegulatorsThe most commonly used regulators in the welding industry are:1. Single-Stage Regulators Reduce cylinder pressure in a single step.More affordable.Suitable for short-term jobs and low production volume. Less sensitive to pressure fluctuations compared to dual-stage models. 2. Dual-Stage Regulators Reduce pressure in two steps: High pressure → intermediate pressureIntermediate pressure → working pressureVery low pressure fluctuation, providing a more stable gas flow.Preferred in high-production facilities. 3. Regulators by Gas Type CO₂ RegulatorsArgon / Gas Mixture RegulatorsOxygen RegulatorsAcetylene RegulatorsPropane / LPG RegulatorsEach gas has a specific pressure and connection type, so regulators are not interchangeable.Key Points to Know When Choosing a Pressure RegulatorSelecting the right regulator directly affects welding performance. Here are the main criteria to consider when making a decision:1. Gas Type Each gas has its own pressure standard and connection type. Incorrect regulator → risk of gas leakage + faulty flow + poor seam quality2. Welding Method and Purpose of useDifferent regulators are required for MIG/MAG welding and TIG welding.For oxy-fuel cutting, oxygen and acetylene regulators are each specifically designed for their respective gases.3. Flow Rate and Flow Precision Precise flow control is critical in professional welding work.For example, in MIG/MAG welding, a gas flow of 20 L/min instead of 12 L/min can cause:Unnecessary consumption,Turbulence,Weld burn defectsCorrect regulator → fixed L/min value + low deviation + controlled source bath4. Production Volume The ideal choice for businesses with continuous flow requirements:• Two-stage,• High flow capacity,• Durable body regulators. 5. Safety Standards The regulator you choose should have the following features:Safety valve against overpressureBurst discSecure connection designCertifications such as CE, ISO, etc.High-quality brass bodySafety is especially critical for oxygen and acetylene regulators. 6. Durability and Service Support In professional use, the regulator is exposed to high pressure for long periods. Therefore:• Availability of spare parts• Ease of authorised servicing• Long-lasting diaphragm and valve mechanism are decisive factors in the choice.Safety Tips for Using a Pressure RegulatorA short but important checklist:• Before attaching the regulator, briefly open the cylinder valve to clear any dust.• Never tighten the connection with a pipe wrench; use the designated tool.• Check for gas leaks with soapy water—never use a flame.• Always keep the cylinder in an upright position.• After use, close the cylinder valve and release the pressure from the regulator.• Do not use the regulator if the gauges are faulty. ConclusionThe pressure regulator at the source is one of the most critical pieces of equipment in terms of quality, safety and gas consumption. An incorrectly selected regulator can cause:• welding defects,• high gas consumption,• workplace accidents,• machine malfunctions.A regulator with the correct gas type, proper flow rate adjustment, safe construction, and high-quality production standards is the foundation of an efficient and safe welding process.

What is a Welding Machine?

What is a Welding Machine?Welding machines are industrial equipment that permanently join metals or certain special alloys using heat, electric arcs and, when necessary, pressure. In today's manufacturing industry, they are central to production in countless areas such as automotive, shipbuilding, defence, pressure vessels, construction and pipelines.In its simplest terms, a welding machine converts the electrical energy it receives from the mains into a controlled welding current. This current creates an arc between the electrode and the workpiece, and the resulting high temperature melts and joins the metal.Basic Components of a Welding MachineUnderstanding a welding machine is easier when looking at its main components:Power Unit (Welding Power Source) Converts AC mains electricity into the appropriate current and voltage required for welding. These can be broadly classified into traditional transformer-based types and modern inverter-based machines.Cables and ConnectorsTransmit welding current from the power unit to the electrode and the workpiece. Using cables of the correct cross-section is critical for both safety and performance. Electrode Holder or Torch Varies depending on the welding method.MMA (Shielded Metal Arc Welding): Electrode holderMIG/MAG: Welding torch with wire feed systemTIG: Torch with tungsten electrodeGround ClampCompletes the welding circuit. A solid and clean connection to the workpiece is essential for arc stability. Control PanelThe section where parameters such as current, voltage, wire speed, and gas flow are adjusted. In modern machines, it is often supported by digital displays and preset programs.Operating PrincipleThe basic operating principle of a welding machine can be summarized in three stages:1. Conversion of Electrical EnergyThe energy drawn from the mains is converted into a suitable welding current by the machine’s internal power-electronics components (transformer, diodes, IGBTs, etc.).2. Arc FormationWhen the electrode briefly touches the workpiece and is then lifted, an electric arc forms between them. The temperature in the arc zone can reach 5,000–20,000 °C.3. Metal JoiningThe high temperature melts the base material and, if required, the filler metal. As the molten area cools, a weld seam is created. Depending on the welding method, this process may occur under shielding gas or under the protective slag of a coated electrode.Welding Machine TypesToday, the most used types of welding machines are:1. MMA (Shielded Metal Arc Welding) MachinesThe most well-known and traditional welding method.The electrode consists of a consumable filler metal and a flux coating.Frequently preferred in heavy industry, construction sites, and maintenance–repair work. Can be used even in windy outdoor environments. Equipment cost is low, and portable models offer advantages in field applications.2. MIG/MAG Welding Machines • These are semi-automatic or automatic welding systems where the wire electrode is continuously fed. As shielding gas:o Inert gases (e.g. argon, helium) for MIG,o Active gases (e.g. CO₂ or mixtures) for MAG.• Offers high welding speed and production efficiency.• Excels in automotive, mass production lines, thin sheet metal fabrication and robotic welding applications.3. TIG (Tungsten Inert Gas) Welding Machines• A non-consumable tungsten electrode is used.• The shielding gas is usually argon.• Provides high weld quality and an aesthetic appearance.• Preferred for critical materials such as stainless steel, aluminium, and nickel alloys.• Workmanship is slower but precision and quality are at the highest level.4. Plasma Cutting and Special Process Machines• These are systems that cut metals at high-speed using a plasma arc.• Some multi-purpose systems may have both welding and cutting functions.• They are suitable for fast, clean and precise cutting of thick materials.Inverter Technology: Modern Welding MachinesToday, inverter technology welding machines offer significant advantages over classic heavy transformer machines:• More compact and lightweight design• Higher energy efficiency• Improved arc stability• Precise current control and digital display• Combination of different welding modes in a single unit (such as MMA+MIG/MAG+TIG)This has enabled more flexible use in both professional workshops and mobile service teams.Areas of UsageWelding machines are encountered in almost all metal manufacturing processes today:• Automotive and related industries• Shipbuilding and shipyards• Pressure vessels, boilers and pipelines• Steel construction and heavy industry• Machine manufacturing• Maintenance, repair and assembly work• Artistic metalwork and workshop applicationsThe welding method, machine power and automation level required differ for each sector. Therefore, selecting the right machine is considered the heart of production.Safety and ErgonomicsWorking with welding machines also carries risks such as exposure to high temperatures, electricity, UV radiation and fumes. Therefore:• Personal protective equipment (welding mask, gloves, apron, work boots) must be used,• Machine grounding and cable insulation must be checked regularly,• The work area must be well ventilated,• Operators must be trained and certified.A properly selected, well-maintained welding machine that complies with safety standards is a fundamental element of both efficient and safe production.2. What You Need to Know When Choosing a Welding MachinePurchasing a welding machine is not just about answering the question, ‘How many amps?’ The welding method you will use, the type of material, the working environment, the operator's experience, and your production goals should be decisive factors in your choice. An incorrectly selected welding machine can:• Causing frequent breakdowns that halt production,• Reducing weld quality,• Increasing energy costs,• Tiring operators and leading to dissatisfaction.Below, you will find the main points to consider when selecting a welding machine, step by step.1. First, Identify Your NeedsProviding clear answers to the following questions is the first step in making the right choice:• Which welding method will you use? (MMA, MIG/MAG, TIG, plasma, etc.)• What materials will you be working with? (black sheet metal, stainless steel, aluminium, castings, etc.)• What is the typical material thickness?• What is the production type?o Fixed production in the workshopo Field/assembly worko Mass production line• How long is the welding time per day?o Intermittent maintenance worko Intensive shift productionYour answers to these questions will determine both the power and technical specifications of the machine.2. Selection Based on Welding MethodMMA Machines• Ideal for use on site, at construction sites, and for maintenance and repair work.• Offers advantages in windy environments or where gas shielding is difficult.• Relatively low investment cost.• Offers a wide range of applications with different electrode types (rutile, basic, cellulose, etc.).MIG/MAG Machines• It is the most preferred solution when serial production and high speed are required.• It has a low spatter rate in thin sheet metal welding, and the weld appearance is aesthetically pleasing.• It has become standard in robotic welding applications.• With suitable gas and wire combinations, it is possible to weld carbon steel, stainless steel, and special alloys.TIG Machines• It excels in applications where the highest stitch quality and aesthetic appearance are sought.• It is the ideal solution for thin-section materials such as stainless steel, aluminium or titanium.• The risk of distortion can be reduced as the heat input is more controlled.• It is preferred for jobs where the work rate is relatively low but quality expectations are high.Whether the machine you choose will focus on only one of these methods or whether you want a multi-process machine is an important factor in your investment decision.3. Current Value and Duty Cycle (Operating Time)Two values frequently seen in technical catalogues are of critical importance:• Maximum source current (A)• Duty cycle (e.g. 200 A at 60%)The duty cycle indicates how many minutes a machine can operate continuously at a specific current within a 10-minute period. For example:• 200 A at 60%:Welding can be performed at 200 A for 6 minutes out of 10 minutes; it is recommended that the machine be allowed to rest for 4 minutes.In businesses with intensive production, the higher the duty cycle value, the more suitable the machine is for production. For a machine that will only be used for intermittent maintenance work, this value may not be as critical.4. Network and Energy InfrastructureWhen selecting a welding machine, you must consider your business's electrical infrastructure:• Will it be single-phase (220 V) or three-phase (380 V)?• Is the mains voltage stable, or is the fluctuation rate high?• Is generator compatibility required for field use?• Is energy cost critical for your business?Modern inverter welding machines offer advantages over traditional transformer-based machines, such as:• Lower energy consumption,• Wider input voltage tolerance,• Smoother arc characteristics.This translates to both savings in energy costs and a more stable welding process.5. Portability and Working EnvironmentThe answer to the question ‘Where will I be welding?’ is also decisive when selecting a machine:• Will you only be working at a fixed station within the workshop?• Will you be going to hard-to-reach locations such as high-rise construction sites, ship decks, or refineries?• Do you have assembly projects that require frequent relocation?In this case:• The weight of the machine,• The carrying handle or wheeled chassis structure,• Cable and hose lengthscome to the fore. Inverter-equipped, lightweight and compact machines provide significant ergonomics in the field.6. User Interface and Digital FeaturesHow operators use the machine is also a selection criterion. Especially in workshops where multiple people work:• A simple and understandable control panel,• Clearly readable digital displays,• Pre-set programmes (such as synergic MIG/MAG),• Memory functions (saving frequently used settings)reduce both workplace accidents and incorrect parameter usage. This directly translates into improved quality, speed, and efficiency.7. Auxiliary Equipment and AccessoriesA welding machine alone is not sufficient; the entire system must be considered:• Wire feed units,• Cooling units (air or water-cooled torches),• Compatible torches and electrode holders,• Gas regulators and hoses,• Transport trolleys, additional cablesWhen selecting a machine, it is important to ensure that all of this equipment is compatible, reliable and durable. The availability of spare parts and service support also play an important role in the selection process.

What is Welding? Types, Applications and Basic Information

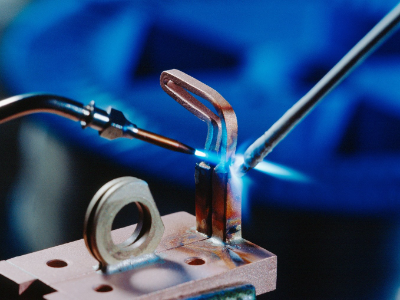

What is Welding? Types, Applications and Basic InformationWelding is the process of permanently joining metal or thermoplastic materials using heat, pressure, or a combination of both. As one of the most fundamental processes in industrial production, welding ensures that products are strong, safe, and durable across a wide range of sectors, from automotive and shipbuilding to pipelines and steel construction.The welding process is based on the principle of melting the surfaces of two materials with controlled heat input and allowing them to cool, forming a molecular-level bond. Filler metal may or may not be used during this process. Depending on the method, welding can be performed manually, semi-automatically, automatically, or using robotic systems.What Is the Main Purpose of Welding? The primary objective of the source is to join two materials in a manner that is:• Strong• Watertight• Durable• Long-lastingA welded joint can often be as durable as the base material, and with the right material and parameters, it can even be stronger.How Is Welding Performed? Although each welding method has its own working principle, the basic process generally involves the following steps: 1. Surface preparation is carried out ( cleaning of grease, dirt, and rust).2. The two materials are positioned at the appropriate distance and angle.3. The welding machine is adjusted to the appropriate current, voltage, and parameters.4. Heat and/or pressure is applied to melt or plasticise the materials.5. If necessary, filler wire is added to the base material.6. After cooling, a permanent bond in the form of a weld bead is formed.The quality of this process depends on many factors, including the machine used, the welding method, the consumables, the operator's skill, and the working environment. What are the Types of Sources?Although there are hundreds of source methods in the world, the methods commonly used in industry are grouped into four main categories:1. Fusion WeldingThe material is heated to its melting point and joined.Common methods in this group include:• MIG/MAG Gas Shielded Arc Welding• TIG Welding• MMA (Shielded Metal Arc) Welding• Submerged Arc Welding (SAW)• Plasma Welding• Oxy-Acetylene WeldingThis is the most widely used method and is central to the metal manufacturing industry.2. Pressure WeldingThe material is not melted; joining is achieved through plastic deformation by applying heat and pressure together.Examples:• Friction welding• Explosive welding• Resistance welding (spot welding, seam welding)• Ultrasonic weldingIt is frequently used in the automotive, electrical-electronic and aerospace industries.3. Thermochemical WeldingHigh temperatures are achieved through chemical reactions.For example:• Aluminothermic welding (rail welding)This is a widely used method for joining rails on railway tracks.4. Brazing and SolderingAlthough not technically included in the welding group, it is among the metal joining methods.• Hard brazing: above 450°C• Soft soldering: below 450°CIt is used in electronics, piping, and fine metal work.Where is Welding Used?The welding method is the cornerstone of modern manufacturing. The main sectors where it is used are:Where is Welding Used?The welding method is the cornerstone of modern manufacturing. The main sectors where it is used are:• Automotive and related industries• Shipbuilding and shipyards• Steel construction and heavy industry• Pressure vessels and boiler production• Pipelines and energy facilities• Defence and aerospace• Machinery manufacturing• Metal furniture and decorative work• Maintenance, repair, and field applicationsIn short, welding is present wherever metal is used.Advantages of WeldingWelding has many advantages over other joining methods:• High strength• Lightweight (no additional materials such as screws or rivets required)• Leak-proof• Flexibility (can be applied to different materials and shapes)• Cost-effective production• Suitability for automationFor these reasons, it is always the preferred method in mass production, large-scale structures, and precision manufacturing.Factors Affecting Welding QualityThe following points are important for obtaining a high-quality weld:• The correct welding method• Suitable welding machine and equipment• High-quality consumables• Correct parameter settings• Operator training and experience• Adequate shielding gas flow• Clean and prepared surfaces• Working environment conditionsErrors in any of these factors can lead to defects such as porosity, burn-through, lack of penetration, and cracks.Why is Safety Important in Welding?Safety precautions are vital because welding involves high heat, UV rays, fumes and molten metal splashes.The following must be used:• Welding mask• Gloves, protective apron• Ventilation and fume extraction systems• Eye and face protection equipment• Electrical safety checks• Fire extinguishing equipmentA safe working environment both improves product quality and prevents accidents.ConclusionWelding is one of the most critical joining processes that form the basis of modern manufacturing. Used in every field, from steel construction to automotive, energy infrastructure to precision manufacturing, this method ensures high strength, long life and safe production when combined with the right equipment, appropriate parameters and trained operators.

Modern Welding Automation with GekaCobot 10

Today, accelerating production lines, reducing costs, and increasing process flexibility are more important than ever. It is precisely in response to these needs that GekaCobot 10 emerges. This robotic welding system, which stands out for its quick deployment, ease of use, and flexible installation, offers businesses a modern automation experience.Graphical ProgrammingProgramming traditional welding robots has always been laborious, difficult to learn, and requires experience. However, thanks to the buttons on the robot arm and its graphical interface, GekaCobot 10Provides easy and intuitive programming,Makes learning easier,Shortens programming time.Teach-Pair Programming: True Collaboration with the RobotOne of the most impressive features of the GekaCobot 10 is its ability to create trajectories by manually dragging the robotic arm. The operator physically guides the robot to the desired position, and the system converts this into a welding program.This feature not only speeds up the process but also gives the user full control, even on complex workpieces.Safety First: Smart Stop and Collision DetectionSafety is, of course, the most critical aspect of industrial robots. The GekaCobot 10 prioritizes safety by immediately cutting off the power with an emergency stop button.In addition, thanks to its collision detection feature, the robot enters self-protection mode in the event of unexpected contact. In hazardous welding environments, this feature is a major plus for both operator and equipment safety.Flexible Operation with Five Different Oscillation PatternsNo two workpieces are the same; every industry and every production process has different welding needs. GekaCobot 10 supports five different welding oscillation patterns: linear, triangular, spiral, trapezoidal, and sinusoidal.This variety allows the system to be used comfortably in both large and small-scale production.Power MIG GPS 5000-R: The Powerful Heart of the SystemThe Power MIG GPS 5000-R welding machine, which works perfectly with GekaCobot, creates excellent welds with different welding modes such as Dual MIG, Pulse MIG, and CV MIG. Thanks to the perfect communication compatibility between GekaCobot 10 and Power MIG GPS 5000-R, data is transmited smoothly without being affected by electromagnetic interference in the environment. This duo works reliably in harsh industrial conditions.PortabilityGekaCobot 10 weighs only 40 kg!The light weight of the GekaCobot 10 stands out as its most important feature that sets it apart from industrial robots. It can be easily transported and set up at different welding stations and quickly put into operation.It is suitable for use on welding tables. It makes your welding tasks easy and enjoyable with welding tables and fixture solutions. Please contact our sales team for welding tables and fixture solutions.Click here for the GekaCobot10 General PDF.Click here for the GekaCobot10 Detailed PDF.

How To Choose a Torch?

How many types of welding torches are there?The torch, which delivers the protective gas and weld metal to the welded area, enables the welder to weld. Torch types also vary according to the welding machine and material. Torches are divided into three types: MIG-MAG type torches, which we call gas metal arc torches; TIG torches used in TIG welding machines and plasma cutting torches.The Machine and the Torch Should Be CompatibleWhen we look at gas metal arc welding torches, the machine and the torch need to have the same amperage. For example, for a 500-amp machine, a torch with a 500-amp carrying capacity should be used. Having a very long torch is also a disadvantage for the welder because transmission problems can occur. The welding torch should be as short as possible whenever possible.How It Is Used Affects the Life of the TorchIncreasing the lifetime is a factor also in the hands of the welder. In the field, welding torches are the parts most exposed to heat. It is the part that is exposed to the most heat right in front of the arc and the bathroom. There are some common usage mistakes that we frequently come across. For example, instead of pulling the machine to move it, the machine is pulled by holding the torch. This damages the connection parts of the torch. Or a piece can fall on the parts of the torch that are on the ground, or it can be stepped on. There should be a place to hang the torch after the welding work is finished. It is possible to increase the service life by cleaning the burrs that splash into the nozzle during welding, or even by spraying a chemical spray. There are Three Consumable Materials In MIG/MAG torches used in gas metal arc welding, the part most exposed to heat is the nozzle. It is made of copper, and some versions are chrome-plated. Just behind the it, there is a component called the contact tip, and behind that is the diffuser, which distributes the protective gas during welding. And right after that, there is a tip holder, which is also made of copper. These are motly the products that we call pure materials, and since the contact tip is the part most exposed to heat, it is replaced at regular intervals. In these, materials containing zirconium are more resistant to abrasion and have a longer service life.It Is Possible to Use LongerFor example, the service life of a contact tip varies depending on its application and the amperage used. However, careful handling by the welder can significantly extend the lifespan of such components. For instance, if burrs stuck to the nozzle is removed by hitting it, the nozzle may become bent, reducing its service life. In contrast, when the nozzle is cleaned using a hand tool, no damage is caused to the part.Types of Torches According to Cooling MethodWater-cooled torches circulate water from the machine's connected cooling unit to the neck of the torch. This water circulation, passing through the torch neck and trigger handle, helps prevent the torch from overheating during welding. In this way, the torch is effectively cooled by water.Air cooling, on the other hand, means that the torch is cooled by the surrounding air. These cooling methods apply not only to TIG welding torches but also to MIG/MAG welding torches.

Welding of Tool Steels

What are Tool Steels, What are their Types?Tool steels are steels with high hardness, toughness or high temperature resistance used in shaping a wide variety of materials by processes such as machining, cutting, drilling, pressing, casting, and forging. It is divided into four groups as cold work tool steels, hot work tool steels, plastic tool steels, and high-speed tool steels:Cold Work Tool Steels: Tool steels used in applications below 200 °C are in this group. Abrasion wear is often encountered on tools. The hard wear resistant carbides required for steels are usually provided with chromium, molybdenum, vanadium, and tungsten. Threading tools, scissor knives, cutting tools, bolt head forging tools, and deep drawing tools can be given as examples to this group.Hot Work Tool Steels: They are tool steels used at temperatures above 200 °C. High temperature resistance is provided by elements such as molybdenum, tungsten, and vanadium. Forging dies, forging tools, casting dies, continuous casting rolls, hot cutting blades, and hammering dies, can be given as examples for hot work tool steels.High Speed Tool Steels: They are tool steels that can remove chips by maintaining their hardness even at high temperatures, in a way that the end of the tool will be hot. In addition to adding elements such as tungsten, molybdenum, and vanadium chromium to the material, hot rolling and special heat treatment suitable for the material should be applied for homogeneous distribution of carbides in order to give the material the desired strength at high temperatures. Cutting and drilling tools that maintain their hardness even at 600 °C can be given as an example for this group.Plastic Work Tool Steels: They are generally used in shaping plastics by injection, extrusion, blowing, and pressing techniques. Compared to other tool steels, they have higher corrosion resistance, polishability, and patterning capabilities. They contain alloying elements such as chromium, manganese, molybdenum, nickel, vanadium, and aluminum.How to Perform the Welding of Tool Steels?Steels containing more than 0.2 percent carbon have low welding capability. Welding of tool steels with a carbon ratio of 0.8 - 1.5% is a very difficult process due to the high risk of cracking. Hence, repair and maintenance welding are applied in tool steels rather than joining. Welding is mainly applied in processes such as hard facing applications of worn surfaces and repair of cracks, except for the joint welds made for the revision of the mold due to the design change and the obligation of combining the prepared parts into a mold.Preliminary Preparation: It is important to control and prepare beforehand the surface of the part before the welding application of the tool steels. Surface cleanliness should be checked and factors such as oil and dirt have to be cleaned before application. Whether there are cracks on the surface of the part or not should be examined visually or with a penetrant test and, if there is any crack formation, it must in any case be cleaned by intervening before welding. “U” welding end should be preferred in welding end design.Preheat: It is important to preheat before welding. Preheating reduces the risk of warping and cracking by reducing the cooling rate. The preheating temperature should be below the tempering temperature of the tool steel and 50-100 °C above the martensitic transformation temperature of the weld metal to be used. During welding, the weld zone should always be kept within this temperature range. Preheating temperature is recommended as 200-300 °C for tool steels made of low alloy steels, 300-400 °C for tool steels made of high alloy steels, 400-600 °C for hot work tool steels, and 400-500 °C for high-speed tool steels. Heating should be slow and homogeneous. The recommended heating rate is 50 °C/hour.Welding Application and Selection of the Filler Material In the welding of tool steels, attempts must be made to keep the heat input low. Welding methods with low heat input such as TIG should be preferred, and if electric arc welding is to be applied, electrodes with as small diameter as possible should be used. It is recommended to weld by using minimum voltage and current parameters in all welding methods.After each pass, the slag cleaning should be performed carefully and lightly hammered while the seam is hot. Slow cooling of the seam after welding is important.Sharp corners and edges should not be allowed to form after welding. Crater formation should be prevented at the end of welding.In hard filling applications that require multiple passes, the number of passes should not exceed 3. Buffer welding can be applied between the base material and the hard filling application.GeKatec 229 SUPER electrodes can be used for buffer welding or GeKa Elox SG 312 MIG or TIG wires for gas metal arc welding applications.In tool steel welding applications, the chemical composition of the tool steel, the heat treatment condition, and the desired hardness value if hard filling is to be applied, play an important role in the selection of the filling material. In normalized tool steels, the chemical composition of the filler material is desired to be the same as that of the tool steel, while in hardened tool steels, the properties such as hardness and temperature resistance of the weld metal are expected to be similar.While GekaTec Tool 60 electrode is used in hard filling applications of cold work tool steels, very satisfactory results are obtained with GeKatec Tool 55 SG and GeKatec Tool 60 SG arc welding wires and rods. The welding filler of GekaTec Tool 60 electrode and GeKatec Tool 60 SG arc welding wires and rods are in the structure of speed steel and are also preferred in hard filling applications of high-speed steels. GeKatec Tool 45 SG welding wire, which is used in filler welding of hot work tool steels, provides very good resistance to abrasion and impact at high temperatures.

Hülya Gedik Discusses Industry and Economic Agenda in Media and Academia

Our Chairwoman of the Board at Gedik Holding, Hülya Gedik, participated in an interview broadcast on CNBC-e at our Gedik Kaynak production facility in Hendek. The program was moderated by Şafak Tükle.During the discussion, current developments in the industrial and economic agenda were addressed. Hülya Gedik shared her insights on global trade balances, Turkey’s competitiveness, and the future of the industry. She also provided perspectives on the operations within our production facilities and Gedik’s strong position in the sector.Bloomberg HT “60 Minutes”: The Impact of International Trade on TurkeyOn September 25, Hülya Gedik appeared on Bloomberg HT’s “60 Minutes” program as the Chairperson of the DEİK Turkey-India Business Council. The discussion focused on the potential effects of the free trade agreement between the European Union and India on Turkey.Hülya Gedik emphasized the significance of this development for both the economy and industry, sharing her views on how changes in global trade dynamics could influence Turkey’s competitiveness and the future of its industrial sectors.Meeting with Students at SUBÜ: Sharing Knowledge and ExperienceOur Chairwoman of the Board, Hülya Gedik, met with the academic staff at Sakarya University of Applied Sciences (SUBÜ) upon the invitation of the Career Center.During the event, she shared her knowledge and experiences with students in an engaging talk aimed at inspiring their career journeys. Hülya Gedik expressed her gratitude to Rector Prof. Dr. Mehmet Sarıbıyık and the Career Center team for organizing the program.

GEDIQ: Gedik Kaynak’s Next-Generation Digital Assistant

Quick, Accurate, and Reliable Access to InformationThe GEDIQ Artificial Intelligence Assistant has been developed to ensure that users can access the information they need quickly, accurately, and reliably. With its comprehensive data structure, it simplifies information access for both individual users and business partners.Easy Access to Product InformationGEDIQ provides detailed descriptions of Gedik Kaynak products. It delivers all items featured in the product catalogs along with their technical details, enabling users to access all necessary information about a product from a single point.Comprehensive Information About Gedik Holding and Group CompaniesThe assistant is not limited to product information—it also shares extensive content about the companies under the Gedik Holding umbrella. This allows users to access up-to-date information about the activities and corporate structure of the Gedik Group.Sales Network and Contact InformationGEDIQ also provides information about the sales network located in Turkey and different regions of the world. Users can easily find the contact details of their regional sales managers and access the dealer networks specific to their location.A New Era in Digital TransformationWith GEDIQ, Gedik Kaynak has taken another user-focused step by digitalizing the process of information access. This AI-powered assistant stands as a tangible example of the company’s digital transformation vision, representing innovation, accessibility, and technological advancement.

Gedik’s Innovative Solutions at Schweissen & Schneiden 2025 in Germany

SCHWEISSEN & SCHNEIDEN 2025 was held from September 15–19 in Essen, Germany. As one of the most prestigious meeting points for welding and cutting technologies, the fair brought together industry professionals from all around the world. Gedik took its place at this major event, showcasing its innovative solutions and wide range of products.International Collaborations and Technology PresentationThroughout the exhibition, visitors were introduced to the latest advancements in welding technologies. At the same time, international collaborations were strengthened, and valuable insights about the future of the industry were shared. This event provided a significant opportunity for Gedik to demonstrate its innovative approach and global vision.62 Years of Experience and a Global VisionWith 62 years of experience and industry expertise, Gedik continues to showcase its leadership and innovative solutions in welding technologies on international platforms. The company’s global vision reinforces its goal of being a pioneer in welding and cutting technologies.

Gedik Kaynak Meets International Visitors at the FABTECH Fair in the United States

Gedik Kaynak showcased its latest welding technologies and innovative solutions to international visitors at the FABTECH Fair held in Chicago, USA. Throughout the event, the company attracted great interest from both industry professionals and participants from various countries. Visitors had the opportunity to receive detailed information about the displayed products and technologies.Turkey’s Expertise Stands Out in International VisitDuring the event, the Consul General of the Republic of Turkey in Chicago, Mr. Tahir Bora Atatanır, and the Commercial Attaché, Dr. Ahmet Samet Tekoğlu, visited the Gedik Kaynak booth. This visit not only strengthened Gedik Kaynak’s position on the international stage but also highlighted Turkey’s expertise in welding technologies at a global level.Gedik Kaynak’s Global VisionIn line with its global vision, Gedik Kaynak will continue to bring the latest advancements in welding technologies to professionals around the world. By maintaining its focus on innovative solutions that make a difference in the industry, the company continues to reinforce its leadership goal in the international market.

Locally Produced GeKaLaser Laser Welding Machines Achieve Their First Sales

The M Series GeKaLaser laser welding machines, developed by our Machinery R&D team, have successfully completed their trial production phase and achieved their first sales. This development holds great significance both for our company and for the Turkish manufacturing industry, as it represents a strong step forward in delivering globally competitive solutions.Advantages of GeKaLaser Laser Welding MachinesThe new generation of laser welding machines stands out with its high-precision laser beam, minimal heat input, and low deformation rate. As a result, they provide much higher quality and more efficient outcomes compared to conventional welding methods.Their high speed and superior seam quality, especially in joining thin sheets and delicate components, make these machines an ideal solution for various industries.Local Production and Competitive Price AdvantageBeing locally manufactured, GeKaLaser machines are offered to the market at competitive prices, reinforcing our brand’s leadership in this field. Developed in Turkey, this technology positions both our company and the Turkish manufacturing industry in a strong and competitive place globally, thanks to its excellence in quality and efficiency.

Innovative Product Launches and Modern Packaging Designs

As Gedik Kaynak, we take pride in being a pioneering brand in the industry since 1963. With our innovative approach and strong infrastructure, we continuously enhance both our product portfolio and brand value.Seamless Cored Wire Launch: A First in TurkeyAs a brand that not only keeps pace with technological advancements but also aims to lead them, we have achieved yet another first in the industry. Known as the “Seamless Cored Welding Wire,” this state-of-the-art product stands out as the first domestically produced seamless cored wire manufactured in Turkey at our advanced production facilities.This achievement positions us strongly not only in the local market but also on the international stage. As one of the few manufacturers worldwide capable of producing this high-tech product, we see it as a tangible reflection of our production capacity and engineering excellence.International Launch in GermanyWe introduced our new product at Schweissen & Schneiden in Germany—one of the world’s most prestigious trade fairs for welding technologies. This significant milestone allowed us to showcase our innovation power on a global scale.With its cutting-edge features, the seamless cored wire adds value to our product range while setting us apart from the competition.Modern and Strong Packaging DesignAlongside the introduction of our new product, we also renewed our packaging designs. Our newly developed modern and robust packaging concept emphasizes the quality and advantages of our products, enhancing our brand’s competitiveness.Visually and functionally improved, this design not only enhances user experience but also reinforces our brand’s strong presence in the industry.Steps Shaping the FutureAs Gedik Kaynak, we remain determined to bring more “firsts” to the industry and to offer innovative solutions. Our seamless cored wire launch and packaging design projects aim not only to meet today’s needs but also to shape the industrial standards of the future. With our innovative vision, we will continue to make a difference in global competition and lead the industry forward.

As Gedik Kaynak, We Have Added Another Innovation that Strengthens Our Leading Position in the Industry

By renewing the design concept of our welding machines product group, we are presenting our users with a more modern, powerful, and technological look.Modern and Technological Design ApproachThe designs of our welding machines, produced under the Gekamac brand, have been transformed into a more contemporary and dynamic structure. These renewed designs not only highlight the strong character of our products more clearly but also aim to enhance the user experience.Our new design launch was successfully carried out at the Schweissen & Schneiden fair held in Germany. This important step has been a strategic development that increased the international visibility of our Gekamac brand.Strong Appearance, Expanding Product RangeOur new designs not only strengthen our brand visually but also expand our product diversity. Our welding machines now feature:• A more modern and powerful appearance,• Enhanced durability,• Technological advantages that bring innovation to the industry,• A user-friendly structure equipped with advanced features.At the same time, our efforts to expand our product range continue with determination. This process enables us to provide stronger solutions to the evolving needs of the industry.As Gedik Kaynak, we continue to lead the sector with our innovative production approach and strong brand identity. The new design of Gekamac welding machines—with its modern look and high performance—will not only enhance our brand’s competitiveness but also provide our users with an advanced experience.This step is a reflection of our strong vision that unites technology with aesthetics.

A New Step in Local Production: Aluminum Wire and Modern Packaging Design

As Gedik Kaynak, we are taking innovative steps to further strengthen our strong position in the industry. While our local production efforts in the aluminum wire product group are rapidly progressing, we have simultaneously completed our modern packaging designs. This development reflects both our commitment to local production and the renewed identity of our brand.Product Range Strengthened by Local ProductionBy focusing on local production in aluminum wire products, we are offering strong and sustainable solutions to the industry. This important step in our production process once again demonstrates our brand’s technological competence and commitment to quality.Along with the new packaging designs, we aim to increase the visibility of our products in the market. This change supports the modernization of our brand’s structure while also enhancing the user experience.New Packaging Design Highlighted with the GeKa BrandThe new packaging designs of our GeKa brand have been renewed to strengthen its visual identity and to communicate the product advantages more clearly. In the design:• The GeKa logo and product visuals were brought to the forefront,• The benefits offered to users were featured directly on the packaging,• A modern and strong brand image was created.With this innovative design, our brand and products will become more visible in the market, increasing our brand recognition. As the stocks of the old packaging designs are depleted, our newly designed products will meet our customers.Continuity in Packaging DesignsWe have also completed the packaging designs for our wire and electrode product groups, further strengthening the visual integrity of our brand. In our new designs, the GeKa logo has been made more prominent, and the advantages of the products have been directly reflected on the packaging.This approach sets a new precedent in the industry while increasing the visibility of our brand. Our goal is to ensure that the GeKa brand achieves a stronger position in the market and that the superior features of our products are clearly highlighted to users.Our Vision for the FutureAs Gedik Kaynak, we continue to add value to the industry by combining our innovative production processes with our modern design approach. With our local production power and modern packaging designs, we aim to further strengthen our brand’s strong position in the market.

GeKa Seamless Flux Cored Wires

What is Seamless Flux Cored Wire?Flux Cored Wires can be produced in two different ways as seamed and seamless. Seamed cored wires are produced by first rolling/forming the steel strip into a "U" shape in the forming machine as in the production of welded pipes and then putting the powder-mix “core” into it and then closing it into a pipe form and drawing it. On the other hand, seamless cored wires are produced by filling the core into a previously formed steel pipe and drawing it to the desired end-product diameter. With the advancement of technology, a faster and more efficient seamless cored wire production process has been developed. In this method, the core is filled into the U-shaped strip as in the production of seamed cored wires, then the strip is rolled into a circular form and the edges are welded seamlessly with a laser beam. Since there is no gap in the seamless cored wires, contrary to the seamed cored wires, the risk of moisture absorption of the core is automatically eliminated. TYPES OF FLUXCORED WELDING WIREWhat are the advantages of Seamless Cored Wire?In Seamless Cored Wires, the risk of hydrogen-induced cracks is minimized as the seamless design prevents re-absorption of moisture. Since seamless cored wires have very low moisture contents in the core and it is virtually impossible to pick up moisture under normal storage and operation conditions, the need for special vacuum packaging is eliminated.Another advantage of Seamless Cored Wires is the possibility of copper coating. Copper coating protects the wire surface against corrosion, prevents friction in the passage through the liner and contact tip during welding and greatly enhances wire feedability. Finally, thanks to the copper coating, the electrical resistance between the wire and the contact tip is considerably low, resulting in a much more stable arc, cooler contact tip and nozzle, thus in turn, reducing nozzle wear and cooling requirements.Since the production of Laser Welded Seamless Flux Cored Wire requires a distinct technology, knowledge, know-how and experience, the number of companies in the world that can offer products with premium quality still is very limited. Gedik Welding is proud to be the only leading and pioneering company in this field in Turkey and has taken its prestigious position in global competition to a higher level.

GeKaWeldSim Realistic Welding Experience